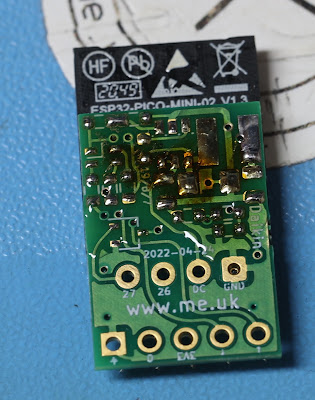

I made the mistake of ordering a board and not ordering the solder paste stencil.

So what to do - well, not a complex board, I tinned the pads and applied some flux as it is a bit sticky...

Then I applied the components. Now this is where I wish I had applied less solder to make it flatter as they did not stay put very well.

Getting flux on the tweezers was also an issue, so lots of cleaning.

Then I cooked in the oven the same as if I had solder paste.

To my utter amazement, it worked perfectly. I did put in a sonic cleaner, which did not help much in cleaning it up...

However, a nylon brush and some IPA, and bingo..

But the damn board works!

So there you have it - an option when you have no stencil!

Nice work!

ReplyDeleteTo get it a little cleaner you could try scrubbing it with a toothbrush and some isopropyl alcohol.

When I do mine by hand I tin just one pad per part then slide the part onto it with a pair of tweezers whilst it's molten and then finish up the other side when everything's in the right place.

Nice work!

ReplyDeleteTo get it a little cleaner you could try scrubbing it with a toothbrush and some isopropyl alcohol.

When I do mine by hand I tin just one pad per part then slide the part onto it with a pair of tweezers whilst it's molten and then finish up the other side when everything's in the right place.

-- andyjpb

When I used to do assembly (best part of 20 years ago) it was common to have a stubby brush(a bit stuffer than a toothbrush) and pot of IPA that dispensed a small quantity into a well at the top when pressed with brush.

ReplyDelete