I have been using JLCPCB to make PCBs for a while. This is for some of the smaller PCB projects at A&A (here), rather than the big projects we do for FireBrick. It means I am learning a lot.

This month I decided to try and have some "assembled" PCBs done. They have a quite nice ordering page allowing you to view the assembled board. This is important as it seems components have no standard for the reference point, nor rotation, and it varies from PCB manufacturer to PCB manufacturer. The tool I found for KiCad is excellent (here), but I did have to make from the GitHub page, rather than using the library/plug-in manager, as that was out of date. Importantly it allows me to add "offset" and "rotation" adjustments needed for placement of parts. That way I can make working production files in one click, which is amazing.

The big challenge in updating various designs was finding parts - the parts they have available readily, without ordering in, are all very similar to what I am using, but often I have to hunt down the right part number. In one case I found that an inductor was not available in the same package, only to find it was if I did not add a part number. Somehow their search found it even though I failed to. The bigger annoyance was the RGB LED I am using, which is low enough voltage to work from 3.3V. They had a load that are the same footprint even but not the low power and low voltage. I ended up using a different part, different footprint, and even sideways mounting, meaning changes to layout, albeit minor.

I still have to work out how to handle some missing parts - the SCD41, for example, around £30, but they (a) have no stock, and (b) list as $150. So that would not be fitted, and I would have to fit. I am wondering if I can put on the soldered pads with some flux and run through the oven I have. I'll have to test that.

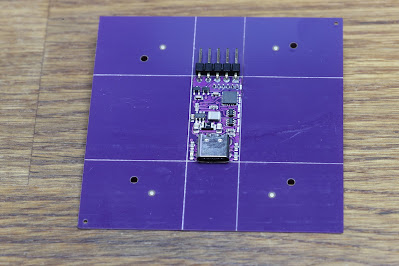

However, for the first board to test the process I ordered the simple Shelly Tasmotizer (here). It does not have a processor, but does have two hand soldered connectors, which was also a good test. They ended up costing £19+VAT each, for a 10 off run, including shipping and assembly and parts. They get a lot cheaper if you order more, of course.

They arrived, and, well, just work. They look really neat. I am impressed.

There are some minor typos/grammar errors in the second paragraph.

ReplyDeleteI use JLCPCB a lot for 3D printer stuff as I run a small online store. They are part of the same company as LCSC and use the same part numbers, but even more useful than that, you can actually order parts through JLCPCB from Digikey, Mouser, etc, which they then keep in stock for you to use in assembly orders.

ReplyDeleteI've done this to have them assemble things from components they don't stock. I was looking at building a Pick and Place machine based on a Voron CoreXY 3D Printer, but JLC are so cheap there just isn't any point!!

Ah, I must find how to do that...

DeleteHover over your username when logged in, click "Parts Manager", then "Order Parts". You can order parts from them (and thereby buy a larger amount at a cheaper price to then be used over multiple orders), or via "Global Parts Sourcing" from Digikey etc.

DeleteIf they don't have something in Global Parts Sourcing, you can click "New Parts Request" and give them the details from DigiKey/Mouser and they will add it to global sourcing, I've done this with OPB666N sensors and they are now available for anyone to order (or, would be, if 3d printer people hadn't hugged global stocks to death!!)

Sorry, last one, it's also worth mentioning they will panel the PCBs for you and they are really good at it, much better than I am myself anyway!! Can make it much cheaper, especially if you are doing single sided PCBs and want to use their "Economic" assembly option which has a cap of 50 pcbs (or 50 panels, which could be a LOT of PCBs)

DeleteI'm designing a PCB for myself at the minute. For sensors I'm going to use LoRa, I've used nRF24L01 before and had sensors sending data back once a minute and been running 5 years on two AA batteries, so great in that respect but range isn't very good and even just a couple of walls can cause some issues, it might not help that they use 2.4GHz so attenuation is greater and the air is pretty saturated with Wi-Fi. LoRa should be similar with battery usage but the range is huge. Testing and connecting to the Helium network I made a connection from 2 miles away to a gateway and no line of site with many houses in between, pretty amazing.

ReplyDeleteI’m still surprised we can get professional PCBs made up in China for so little money, and now they will even assemble boards for not much more, although for me I quite enjoy assembly and don’t find SMD parts, even the small ones, are two difficult to work with, provided I order a stencil at the same time.

I’ve also found the Nextion range of LCDs are pretty good and easy to use, and any microcontroller with serial can talk to them and it’s really easy to build a nice looking interface.